Project Description

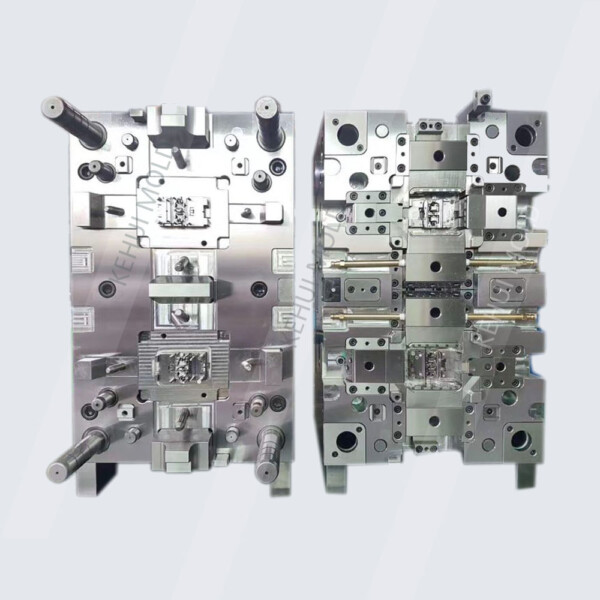

This is a Auto Parts Mold we made, the molded part with honeycomb feature, and the mold has one slider and one inclined slider. Cooling blocks are installed for easy cooling connecting. Moldmaker LLC is an injection mold factory in Dongguan City in China, with sophisticated technology for making automotive interior, exterior, lighting system and industrial part molds. At the same time we are also concern on other field, like electronic and home appliance. Complex geometries, exacting tolerances and the realization of tools for fully automatic production are our stock-in-trade.

What tapes of molds we make?

- Single and multi-cavity molds

- Cold and hot runner tools

- Automotive molds

- Home appliance molds

- Double injection molds

- Insert overmolding

- Reverse molding (injection and ejection on one mold half)

- Prototype tools

- Die casting tools

Why choose us?

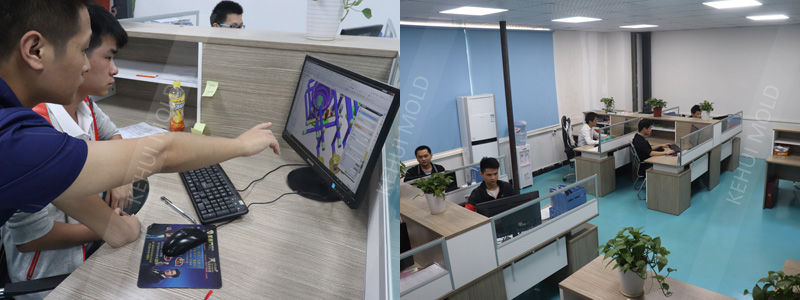

- Professional Engineering Design

Team of full time professional mold designers with more than 10 years experience on mold design.

We are providing Product Design feasibility study from the concept to real part ,tooling optimization, project appraisal and solution proposal.

- Mature management with profesional technical communication in English

Our project management team are good at English and have strong technical back ground, could follow your project and communicate with you on technic points fluently.

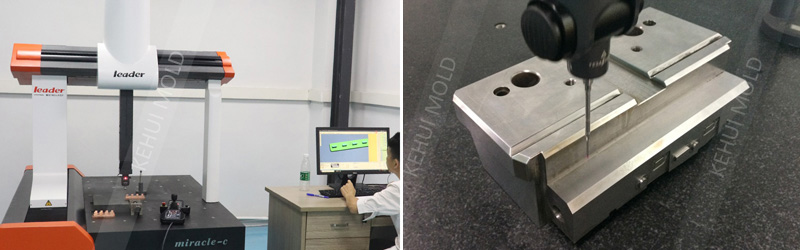

- Advanced Equipment

With our high precision equipment (Hi-speed CNC machining center, Slow-feeding wire-cut, Mirror EDM and CMM inspection machine) we can control all the tolerance of all parts as requested.

- Strict quality control procedure

We have a professional QC department as well as with precise inspection equipment. We will inspect every part after every process to insure there is no problem then we can go the next steps. Finally make measurement report for mold components, FAI report for trial samples of mold. Make sure everything is OK before shipping.