Project Description

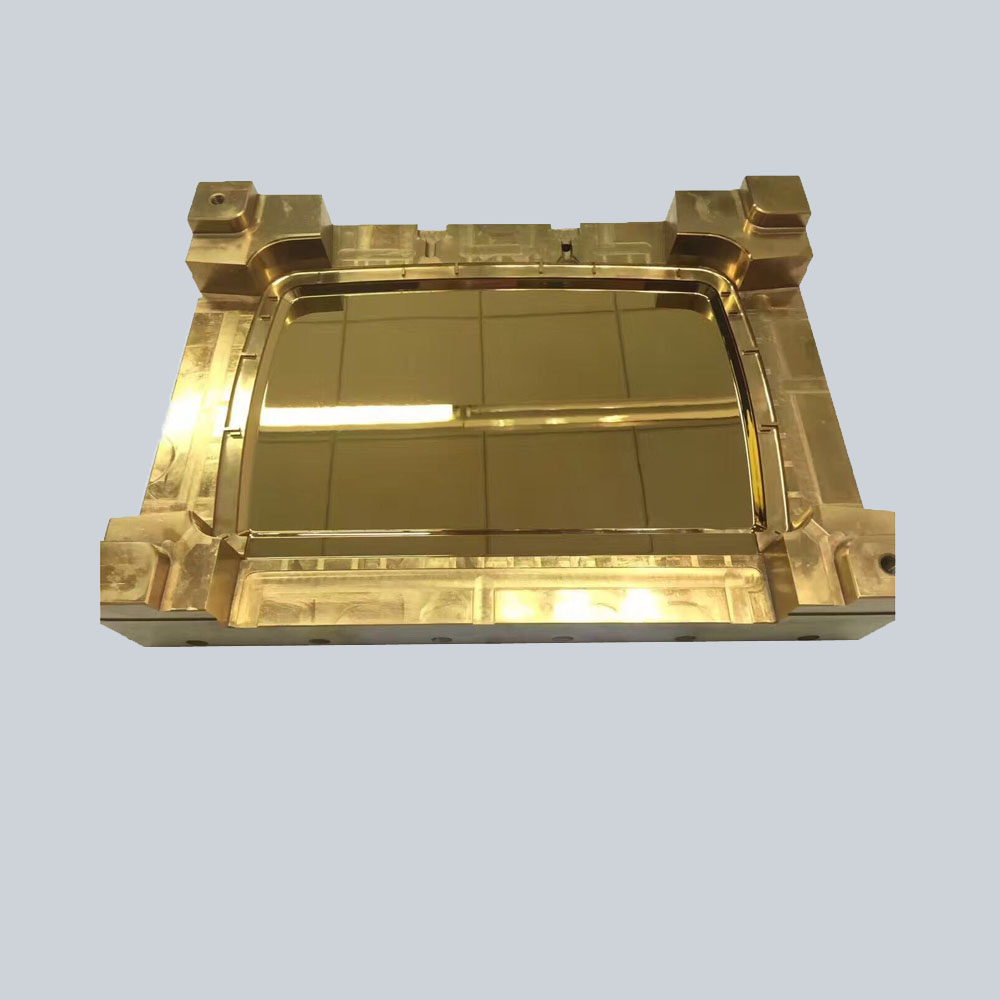

CNC Milling Service is used to apply a machined surface finish on engineering-grade plastic or metal or for creating complex 3D shapes. Moldmaker LLC use high Precision Cnc Machining centers with quick-change tooling. Moldmaker LLC toolpaths the digital part design to our CNC machines. During the machining process, a solid block of material is clamped into a CNC mill and cut into a finished part. The range of material choices allows parts to be made with the desired material properties, and good tolerances yield parts suitable for form, fit and function testing.

| Basic Information | PARAMETERS |

|---|---|

| Size: | 120 X 75 X 30mm |

| Material: | 1.2343 ESU |

| Hardness: | 48+2 HRc |

| Function: | CNC Prototyping Parts |

| Documentation: | Inspection report, Material certificate |

| Process tolerance: | +/-0.005mm |

| Manufacturing Lead time: | 14 Days |

| Transportation lead time: | 3 Days (to Germany) |

| HS code: | 84879000 |

| Quality Management System: | ISO9001, 6S Principle |

Advantages of CNC Milling Service:

- Show your customers and investors a model of your product.

- Demonstrate the appearance, dimensions and features of your product.

- Test your design for its suitability.

- Save time and money by identifying and reducing design flaws.

- Improve and streamline the production process.

- Reduce your work load when the time comes to manufacture.

- Create multiple versions with different colors, surface textures and finishing processes.

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

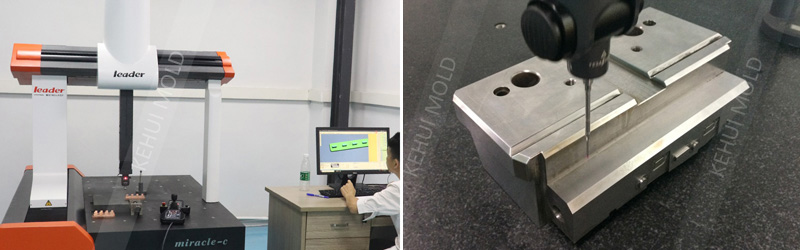

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

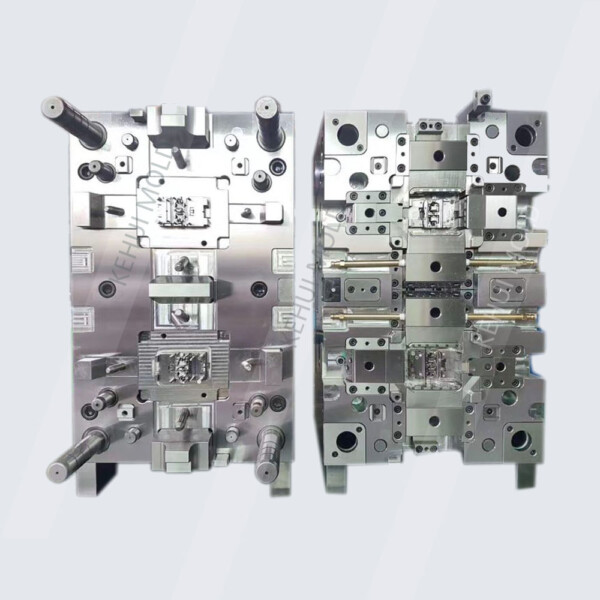

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.

Engineering Design

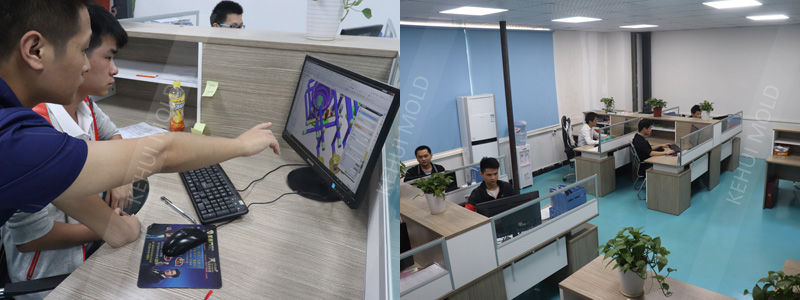

We have 8 Full Time experienced Tool Designers and 20 years experience design manager. So that we can provide Product Design feasibility study from the concept to real part, tooling optimization, project appraisal and solution proposal.

Advanced Equipment

Our professional and aspiring team of engineers and technicians work in a clean and tidy environment use the advanced equipment, to turn your concepts into reality quickly, accurately and at a great price. You design it and we will make it.

Project example: