Project Description

Moldmaker LLC is a professional tooling and engineering company. We also provide Customized Machine Parts of mold tools and other industrial uses.

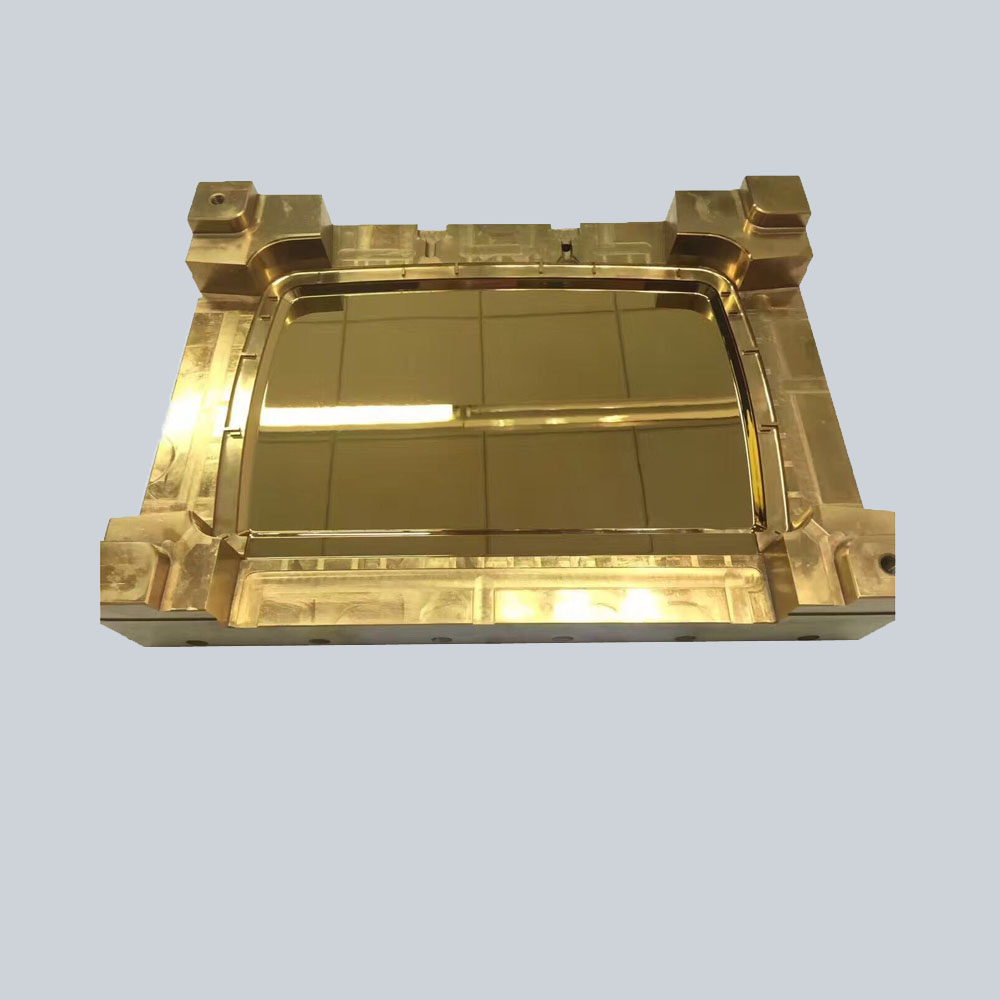

Core and Cavity Insert is part of mold, it is used for 5 reasons. First, nlaid inserts in the exhaust difficult place can easily exhaust. Second, it is convenient for mold change, Third, the mold on the protruding place inlaid inserts can save mold height and save cost. Fourth, difficult to process the place, inlaid pieces can be easily processed. Fifth, in a lot of water can not get the place, you can set the beryllium copper to cool.

If you are interest our service and want to try this way to your new project, feel free contact us directly, we will always do our best to support you.

| Basic Information | PARAMETERS |

|---|---|

| Size: | 20X120X80mm |

| Material: | 1.2343 |

| Hardness: | 52+2 HRc |

| Function: | For injection mold demolding |

| Documentation: | Inspection report, Material certificate |

| Process tolerance: | +/-0.01mm |

| Manufacturing Lead time: | 20 Days |

| Transportation lead time: | 3 Days (to Germany) |

| HS code: | 84804100 |

| Quality Management System: | ISO9001, 6S Principle |

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

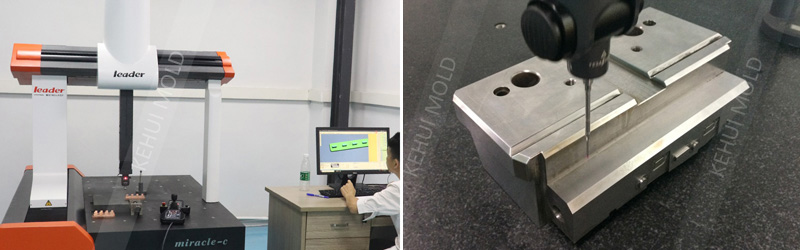

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.

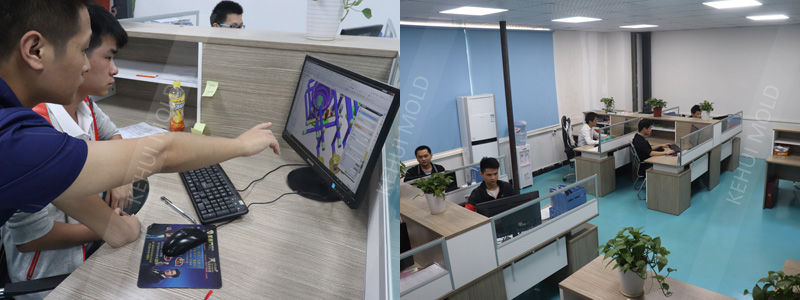

Engineering Design

We have 15 Full Time experienced Tool Designers and 20 years experience design manager. So that we can provide Product Design feasibility study from the concept to real part, tooling optimization, project appraisal and solution proposal.

Advanced Equipment

Inspection Center

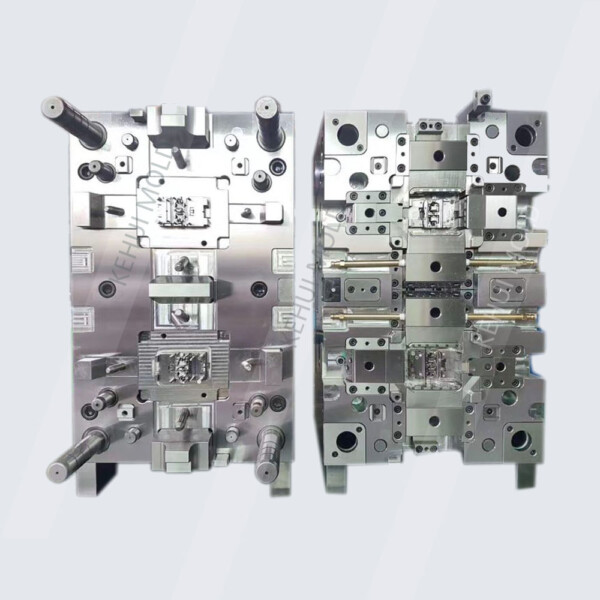

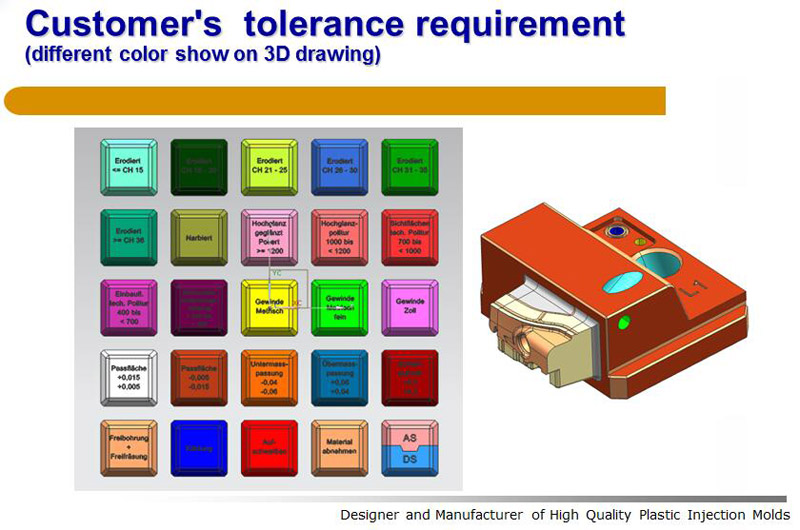

Customized Machine Parts Project example