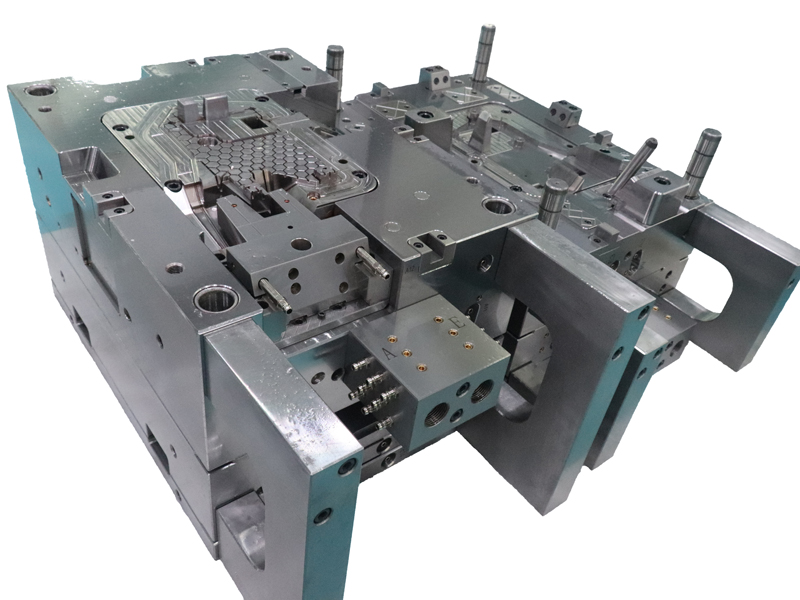

Tooling & Injection molding services

We are dedicated to making the finest parts and products for our customers. We offer all services under one roof for Mold Tooling, CNC Machining & Injection Molding. With more than 8 years of success, we are recognised as a precision mold manufacturer. If you can design it, we can make it. These are some of our processes available in-house :

Management of mold project

- Collect client’s original data

- Make the historical records of the project

- Summon the project-designing meeting

- Send drawings for customer’s approval

- Organize manufacturing

- Follow up design and manufacture schedule

- Keep customer posted on every procedure by production records and photos

- Self inspect & confirm plastic sample

- Get clients’ approval

- Arrange the shipment of mold

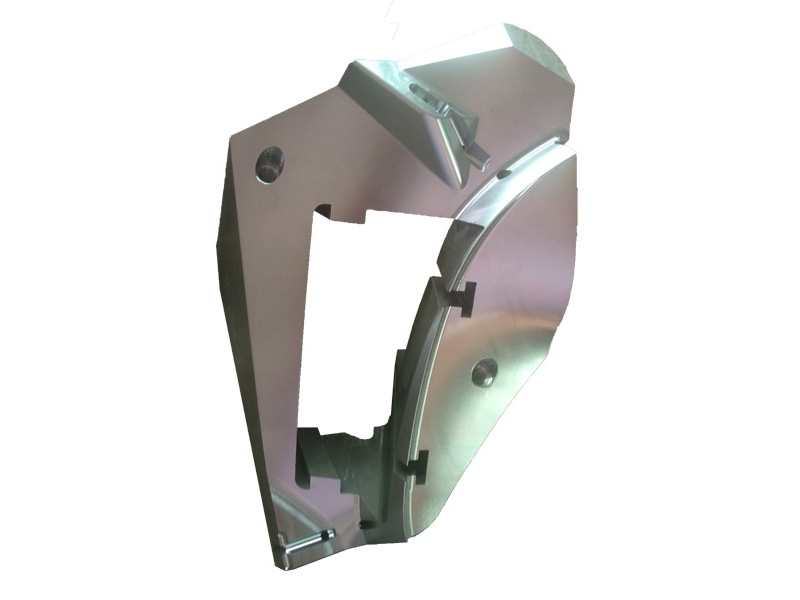

Management of parts project

- Collect client’s original data

- Make the historical records of the project

- Summon the project kick off meeting

- Organize manufacturing

- Follow up part detail drawing and manufacture schedule

- Keep customer posted on every procedure by production records and photos

- Self inspect & confirm the spare parts are qualified

- Get clients’ approval on inspection reports

- Arrange the shipment of mold

Management of production project

- Collect client’s original data

- Make the historical records of the project

- Make work instruction manual

- Catch up the production schedule

- Inspect the plastic sample

- Send FAI report and golden sample (or photos) for customer’s approval

- Hold production lauch meeting

- Start production according to customer proved sample

- Ship the products with CPK report.