Project Description

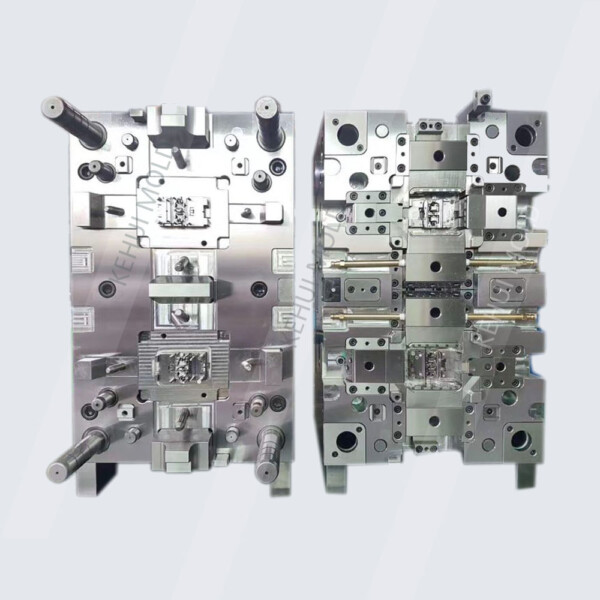

CNC Prototype Machining is ideal for making CNC Prototyping Parts from plastics or metal and which look and feel like production made parts. They are able to achieve tighter tolerances with better surface finishes than other prototyping methods. Our machined prototypes have all the features needed to make a fully functional part, including tapped and threaded holes and precisely flat mating faces.

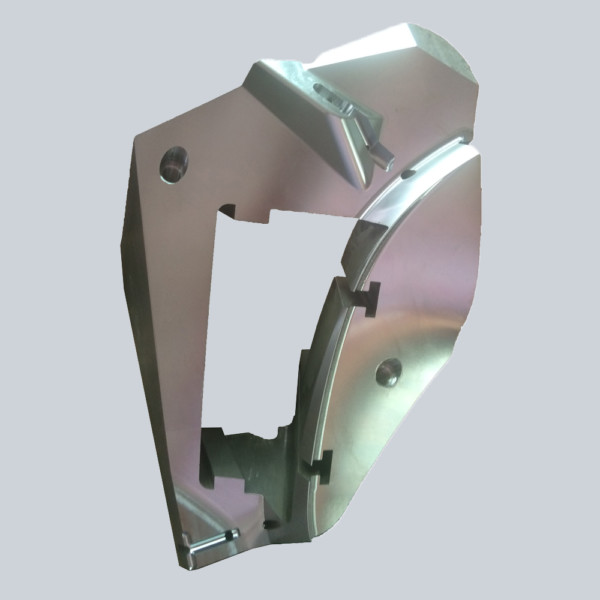

| Basic Information | PARAMETERS |

|---|---|

| Size: | 120 X 75 X 30mm |

| Material: | 1.2343 ESU |

| Hardness: | 48+2 HRc |

| Function: | CNC Prototyping Parts |

| Documentation: | Inspection report, Material certificate |

| Process tolerance: | +/-0.01mm |

| Manufacturing Lead time: | 14 Days |

| Transportation lead time: | 3 Days (to Germany) |

| HS code: | 84879000 |

| Quality Management System: | ISO9001, 6S Principle |

Advantage of CNC Prototyping:

- Show your customers and investors a model of your product.

- Demonstrate the appearance, dimensions and features of your product.

- Test your design for its suitability.

- Save time and money by identifying and reducing design flaws.

- Improve and streamline the production process.

- Reduce your work load when the time comes to manufacture.

- Create multiple versions with different colors, surface textures and finishing processes.

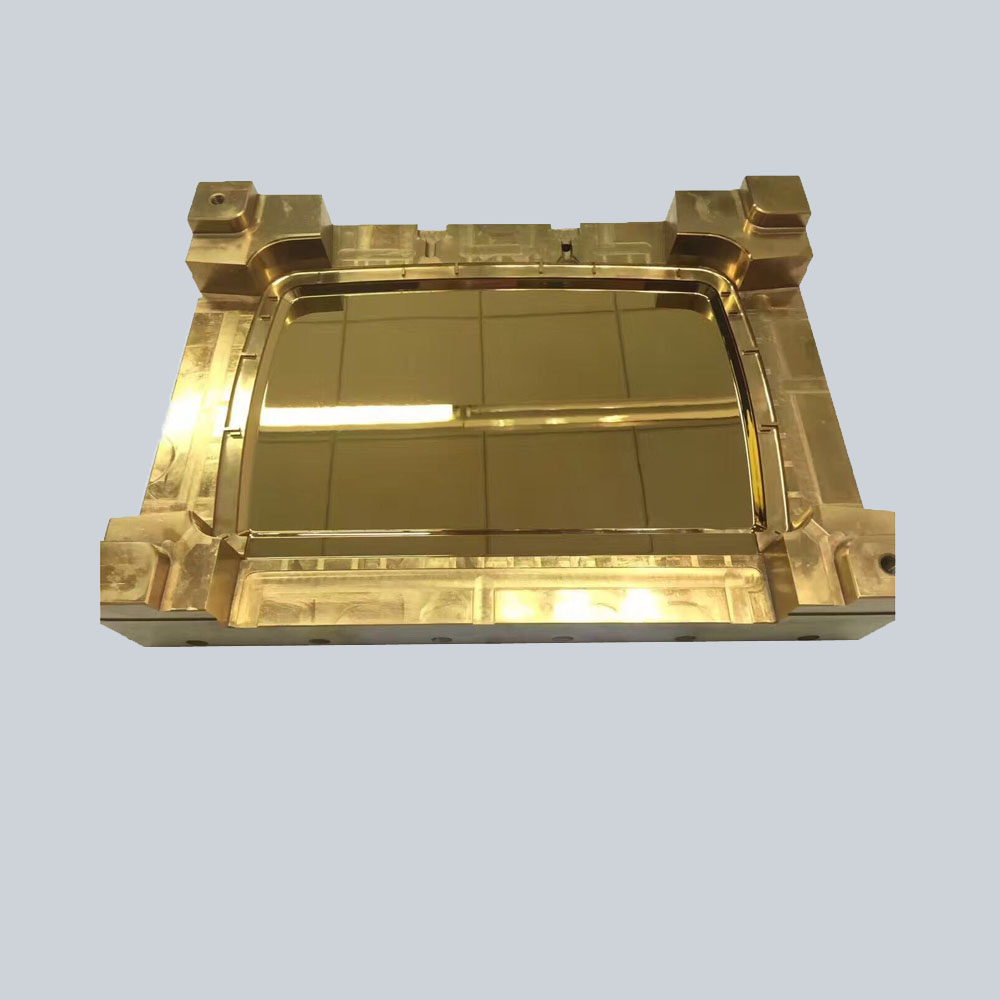

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mass production CNC parts.