Project Description

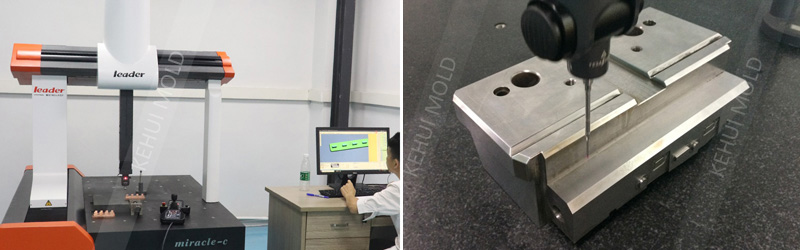

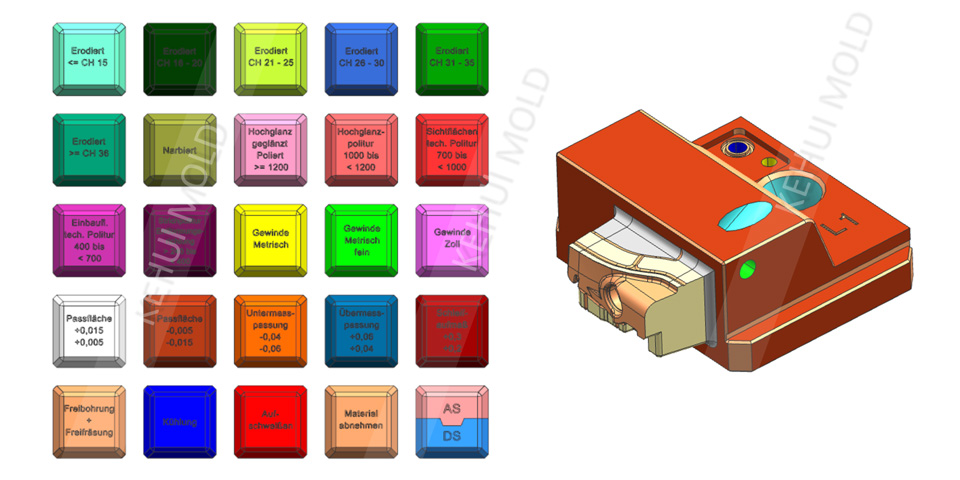

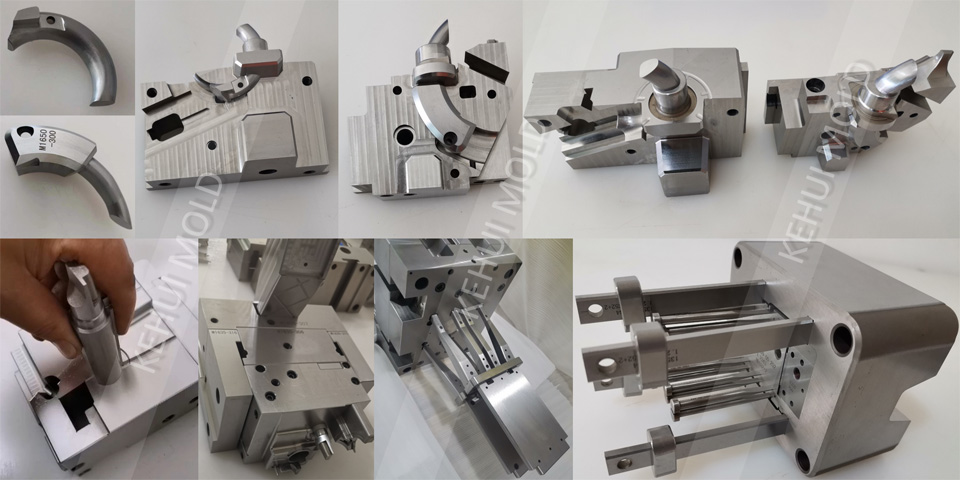

Moldmaker LLC Limited specializes in making and design precision molds, mass production of plastic injection parts. As a Injection Moulding Manufacturer, we provide Custom Machining Services and Making Injection Molds. Moldmaker LLC was established in 2014, located Dongguan, China. We have high-tech mold designing capability and have a full set of machining center. We are equipped with advanced facilities of CNC Machining Center, CNC Wire Cut Machine, Milling Machine, Precision Grinding Machine, CNC Electric Discharge Machine (EDM) and 2&3 Dimension Measuring Instrument.We have 16 sets of injection molding machines, have capability to do mass plastic injection after the mold is finished. We are very happy received RFQ from you side and build long-term business ship with your esteemed company.

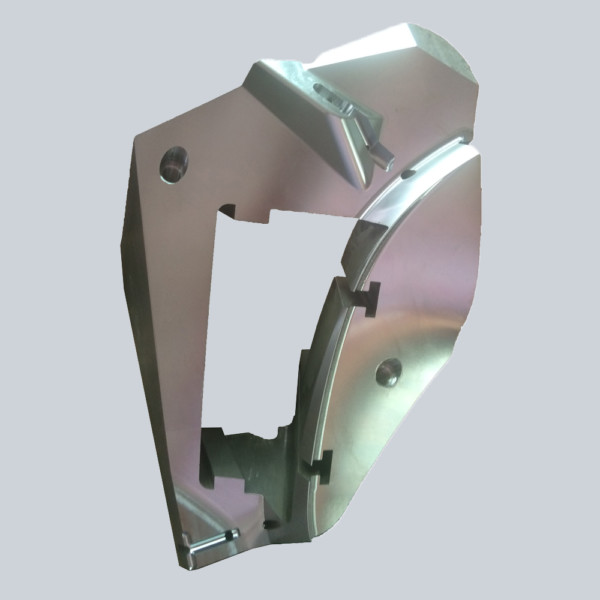

| Basic Information | PARAMETERS |

|---|---|

| Size: | 350 X 350 X 75mm |

| Material: | 1.2343 |

| Hardness: | 52+2 HRc |

| Function: | Core and Cavity for injection mold |

| Documentation: | Inspection report, Material certificate |

| Process tolerance: | +/-0.01mm |

| Manufacturing Lead time: | 14 Days |

| Transportation lead time: | 3 Days (to Germany) |

| HS code: | 84807190 |

| Quality Management System: | ISO9001, 6S Principle |

The advantages of ordering Custom Mold Components:

1.Save lead time

You can looking for several suppliers to finish the same project together. For example: arrange A company to design, B factory making mold base, C factory making core block, D factory making slider/lifter/insert etc (request every supplier control the tolerance within your requirement, so that is easy to assembly). E factory (in your country) assembly and trial . For the normal procedure from design, process, fitting, trail to final shipping out may need at least 3 month. But in this way we can finish all the projects by 1 month, save the lead time considerably.

2.Save cost

You company can save a lot of time, cost and manpower of traveling abroad to trial the tooling, and much Better improve the work efficiency . If mold base made in your country other parts made in china that you can save a lot of time & delivery cost, and also you can save delivery cost of plastic material from your country to China.

3.Quality insurance

With our high precision equipment (Hi-speed CNC machining center, slow-feeding wire-cut, mirror EDM and CMM inspection machine) we inspect them after finish every process, so we can control all the tolerance of all parts as requested, and The parts be shipped after the inspection report to be past by customer. In this way we have fully controlled every part, so that we can save the cost to preventing trial the mold again and again.

Why ordering Custom Mold Components from us?

1. High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

2. Mature experience with precision equipments we use. We make every component according to the tolerance of your requirement. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

If you order the mating parts together we will try the fitting and assembly for you before shipping.

3. Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.