Project Description

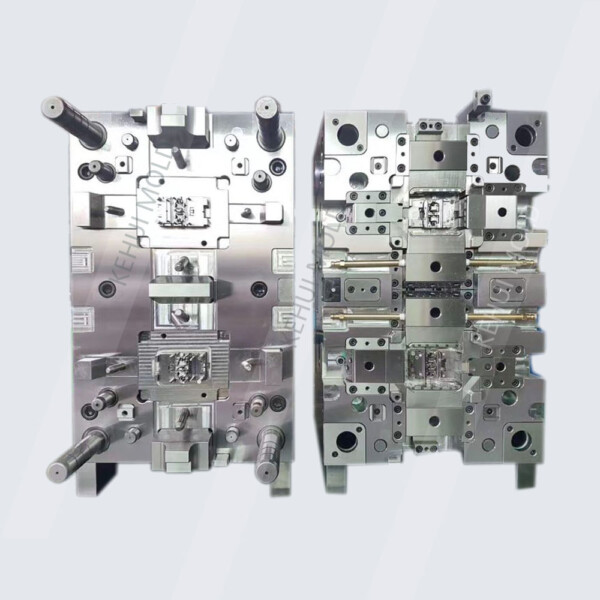

A mold can be well built but, if it isn’t designed well, it doesn’t perform well. Our company builds molds in house, our engineers evaluate every mold design professionally. Molds are not authorized to begin without our approval because we guarantee it!

We are provide customized Plastic Tooling Making service. We are in this field more than 10 years experience.

We not only make whole molds but also supply custom mold components such as mold inserts, mold sliders, lifters, core and cavity blocks, ejector pins, with DHL or TNT delivery just take 3 days to your company. Then you can doing assembly by themself. If your company never purchase Injection Mould Tool from other country, you maybe can try this way, just purchase mold components first. Due to this way can reduce your molding cost, meanwhile you can control your molding quality, And your company have more competitive in your country with very low risk.

We have some customers, before they never purchase Injection Mould Making from other country, even they not know the import process, but now we are work together very well. If you want to know more detail about this, please let me know, I will told you more details.

What tapes of molds we make?

- Single and multi-cavity molds

- Cold and hot runner tools

- Automotive molds

- Home appliance molds

- Double injection molds

- Insert overmolding

- Reverse molding (injection and ejection on one mold half)

- Prototype tools

- Die casting tools

Why choose us?

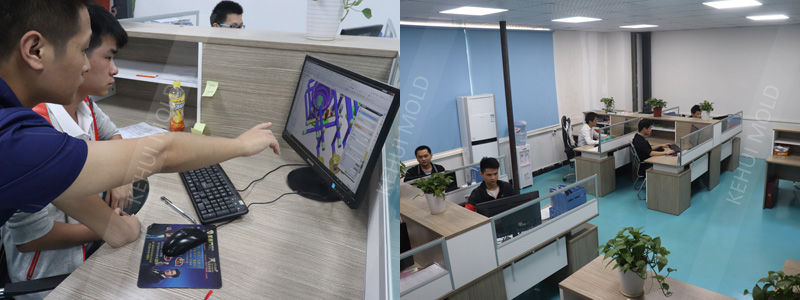

- Professional Engineering Design

Team of full time professional mold designers with more than 10 years experience on mold design.

We are providing Product Design feasibility study from the concept to real part ,tooling optimization, project appraisal and solution proposal.

- Mature management with profesional technical communication in English

Our project management team are good at English and have strong technical back ground, could follow your project and communicate with you on technic points fluently.

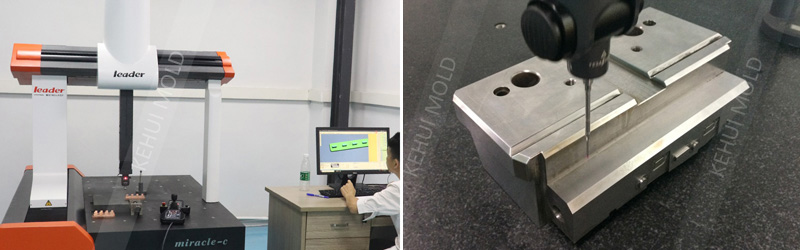

- Advanced Equipment

With our high precision equipment (Hi-speed CNC machining center, Slow-feeding wire-cut, Mirror EDM and CMM inspection machine) we can control all the tolerance of all parts as requested.

- Strict quality control procedure

We have a professional QC department as well as with precise inspection equipment. We will inspect every part after every process to insure there is no problem then we can go the next steps. Finally make measurement report for mold components, FAI report for trial samples of mold. Make sure everything is OK before shipping.